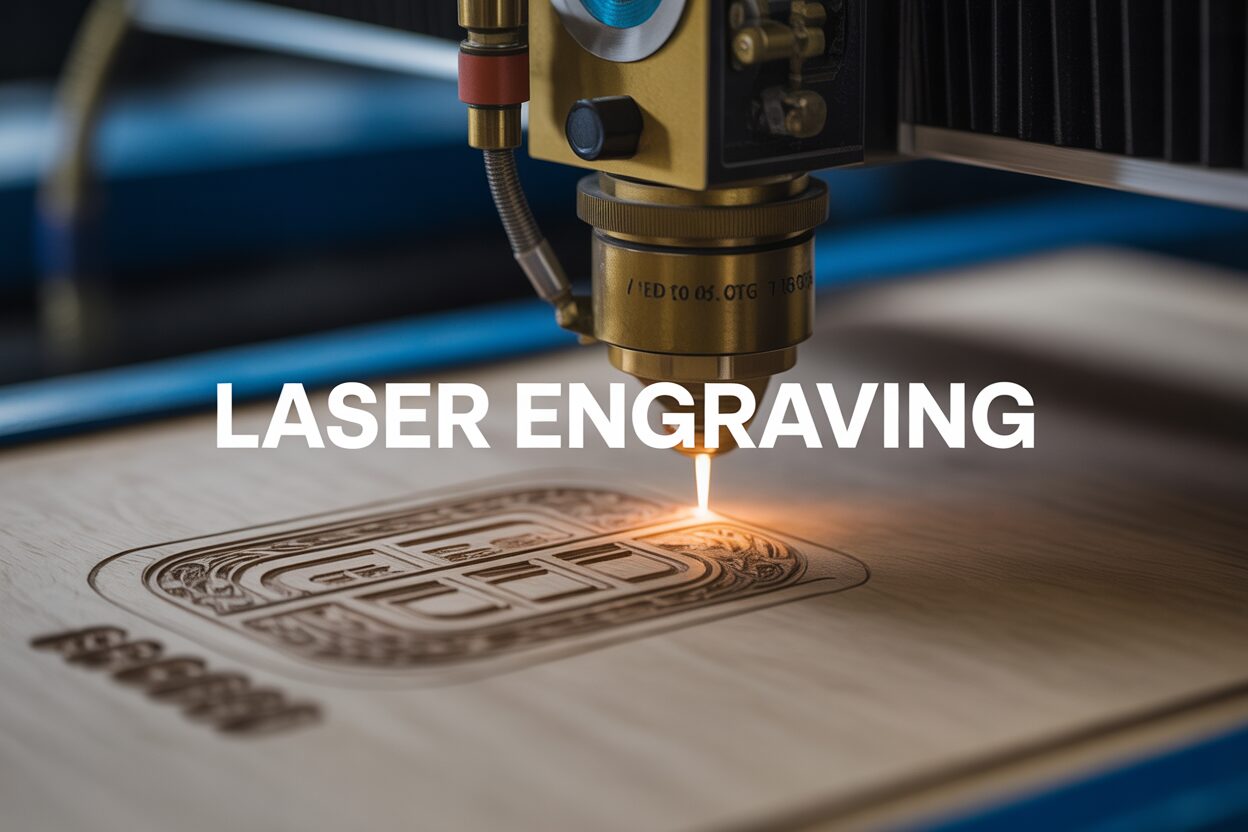

Precision and personalization have become essential in today’s product design and manufacturing processes. A laser engraving machine plays a transformative role in helping industries, artists, and entrepreneurs turn ordinary materials into personalized masterpieces. This technology has grown far beyond industrial use, now reaching hobbyists, small business owners, and creative professionals who are constantly pushing the limits of design.

Laser engraving machines operate by using a concentrated beam of light to alter the surface of a material. Unlike traditional methods, which involve physical contact, a laser engraver offers a contactless solution that reduces wear and ensures precise detailing. The technology supports a wide range of materials, including wood, glass, acrylic, leather, metal, and even certain fabrics, making it a versatile choice across creative disciplines.

Content

A New Standard in Design and Manufacturing Versatility

The appeal of a laser engraving machine lies in its flexibility and efficiency. Whether used for industrial marking or personal artistic projects, it brings a level of refinement that’s hard to achieve through manual or mechanical means. Companies use this technology to etch serial numbers, logos, and product information, ensuring permanent marks that resist fading, corrosion, or removal. The permanence of the output is critical in fields like aerospace, medical devices, and electronics, where traceability and identification are non-negotiable.

In the realm of art and design, the possibilities are nearly endless. Laser engraving allows for detailed patterns, text, and illustrations to be embedded onto everyday objects, turning them into custom works of art. Wedding gifts, corporate giveaways, home décor, and smartphone accessories are just a few examples of how creative professionals harness the power of laser engraving. The ability to engrave on curved surfaces or complex textures further opens the door to innovative product offerings.

Time is another factor that makes the laser engraving machine invaluable. Automated software handles intricate jobs with consistent quality and minimal errors. The repeatability ensures that whether a user is producing one item or a thousand, the final result is reliably identical. This efficiency not only saves time but also reduces material waste, which is a growing concern across many industries.

Choosing the Right Machine for the Job

Selecting the appropriate laser engraving machine involves careful consideration of several factors. Power output, engraving speed, compatibility with materials, and maintenance requirements all impact performance. Lower-powered desktop models are suitable for small-scale projects, especially for hobbyists or boutique operations working with wood, plastic, or paper. On the other hand, high-powered industrial units are designed to engrave harder surfaces such as stainless steel or stone at greater depths and faster speeds.

Another essential element to evaluate is the laser type. CO₂ lasers are the most common and affordable, making them ideal for cutting and engraving non-metallic surfaces. Fiber lasers, by contrast, are more specialized and offer superior results on metals, producing clean marks without requiring additional surface treatments. Diode lasers, while less powerful, are compact and budget-friendly, often used for engraving soft materials in home workshops or educational settings.

Software integration is also worth examining. Most modern laser engraving machines come with design software or support industry-standard formats. Compatibility with vector graphics and raster images makes it easy to import or create custom designs. This user-friendly approach broadens the range of potential applications, from personal monogramming to prototyping parts for engineering.

Ventilation and safety features are critical, especially in enclosed or indoor settings. Fumes generated during the engraving process can pose health risks depending on the material, so proper filtration or exhaust systems are vital. Machines with built-in safety features, such as auto shutoff sensors, flame detectors, and protective enclosures, are recommended for both home users and commercial operators.

Driving Business Growth Through Customization

In recent years, the demand for customized products has surged across nearly every consumer category. Businesses now leverage laser engraving machines to meet this demand with precision and scalability. From engraving names on jewelry to branding promotional items, the machine becomes a revenue-generating tool rather than just a creative outlet.

E-commerce platforms have made it easier than ever to monetize customized goods. Many small businesses offer made-to-order products like engraved tumblers, cutting boards, plaques, and signage. The laser engraving machine enables fast turnarounds without sacrificing quality, which is critical in maintaining customer satisfaction. Customers who receive personalized items are also more likely to associate those products with a premium, memorable experience.

In corporate environments, the machine serves additional purposes. Companies use laser engraving for internal operations, such as asset tracking, security tags, and equipment labeling. The engraved markings can withstand industrial conditions where labels or stickers would otherwise degrade. This level of durability and traceability reduces long-term costs associated with replacement and lost items.

The technology also contributes to brand differentiation. Customization strengthens emotional connections between consumers and products. Whether it’s a custom engraving on a leather wallet or a limited-edition run of engraved wine bottles, these touches create a unique brand story. Businesses that invest in a laser engraving machine find it easier to stand out in saturated markets where originality and craftsmanship are valued.

Advancements That Shape the Future of Laser Engraving

Recent developments in laser technology continue to enhance the precision, speed, and accessibility of engraving machines. Compact designs now offer industrial-grade performance without taking up extensive workspace. This shift allows more people, from students to entrepreneurs, to explore the capabilities of laser engraving without a steep entry cost.

Integration with digital tools such as cloud-based design libraries, Wi-Fi connectivity, and mobile apps has made these machines even more intuitive. Some models allow remote monitoring or job queuing from a smartphone or tablet, making it possible to manage production from virtually anywhere. These enhancements reduce downtime and streamline creative workflows.

Artificial intelligence is also beginning to influence the field. Some software can now auto-detect shapes, suggest settings based on materials, or generate previews to ensure proper alignment before engraving begins. This not only increases accuracy but also builds confidence among new users unfamiliar with technical parameters.

In educational settings, schools and maker labs are using laser engraving machines to teach students about engineering, design, and entrepreneurship. The hands-on experience fosters creativity while introducing learners to valuable tech skills. As more people become familiar with the technology, its applications are expected to expand into new industries and disciplines.